Umugqa womshini wokugcwalisa i-Glass Bottle Liquor

Qhudelana Nengilazi ye-Glass Bottle Whisky Filler Machine Line Line

Izici:

Izinto zomshini ezixhumana nalolu ketshezi zenziwe ngensimbi engenasici esezingeni eliphakeme, Izinto ezibucayi zenziwa yithuluzi lomshini elilawulwa ngamanani, futhi wonke umshini wesimo ungaphansi kokutholwa inzwa ye-photoelectric. Kungenxa yezinzuzo zokuzenzekelayo okuphezulu, ukusebenza okulula, ukumelana okuhle okuqinile, ukuzinza okuphezulu, isilinganiso sokuhluleka okuphansi, njll.

Singaphinde sihlomise ulayini wokukhiqiza ubhiya ngemishini yokwelashwa kwamanzi, uhlelo lwangaphambi kokwelashwa imishini yokuxuba, kanye nohlelo lokupakisha kufaka phakathi umshini wokulebula wemikhono, Nciphisa umshini wokupakisha njll njengomugqa owodwa ophelele.

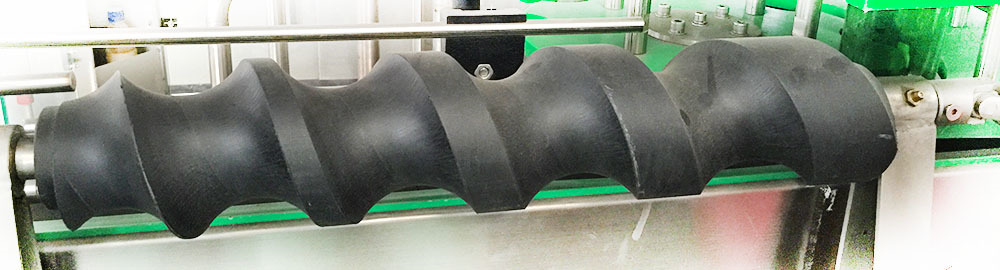

1.Screw feeder for Glass Bottle

2.Whisky bottle Washing Filling and Capping Machine

umshini wokugcwalisa i-whisky uhlanganisa ukuwashwa kwamabhodlela, ukugcwaliswa kwe-whisky nokufaka ku-monobloc eyodwa, futhi izinqubo ezintathu zenziwa zigcwele ngokuzenzakalela. Isetshenziselwa ukugcwaliswa kwamanzi amaminerali, amanzi amsulwa, nezinye iziphuzo ezingekho kaboni (njenge-whisky). Ezakhiweni zikagesi, sisebenzisa iMitsubishi, i-Omron, iSchneider, i-Airtac, njll okungumkhiqizo odumile futhi onekhwalithi eqinisekisiwe. Into ngayinye yomshini ethintana nalolu ketshezi yenziwe ngensimbi ephezulu engenasici. Izingxenye ezibucayi zenziwa yithuluzi lomshini elilawulwa ngamanani, futhi isimo sonke somshini singaphansi kokutholwa yizinzwa ze-photoelectric, akukho bhodlela elingagcwaliswa, akukho bhodlela elingenayo i-capping. Kungenxa yezinzuzo zokuzenzekelayo okuphezulu, ukusebenza okulula, ukumelana okuhle okuqinile, ukuzinza okuphezulu, izinga lokwehluleka okuphansi, njll. Ikhwalithi ifinyelela ezingeni eliphakeme lomhlaba jikelele. Kungukukhetha okungcono kakhulu kwabatshali bezimali bakhiqiza iziphuzo ezintsha nezindala.

Isici:

● Ngesakhiwo sokudluliswa kwentamo yebhodlela, ukuhanjiswa kwebhodlela kuzinzile; kulula kakhulu futhi kuyashesha ukusebenzisa amabhodlela ahlukene ukugcwalisa kumshini ofanayo ngokulungisa ukuphakama kwe-conveyor nezingxenye eziningana zokushintshana.

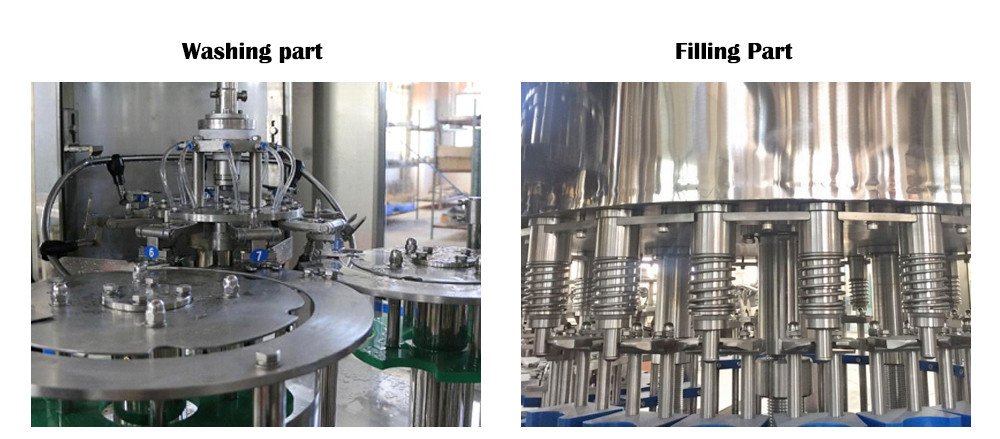

● Ngomqondo wokugcwalisa amandla adonsela phansi, isivinini sokugcwalisa siyashesha futhi ukunemba kuphezulu; izinga lokugcwalisa liyashintshwa.

● Ngomshini wokuhlanza uhlobo lwentwasahlobo, amabhodlela angenalutho aphendulwa ngo-180 ° kulayini oqondisayo wokuhlanza ngaphakathi; umlomo wombhobho wokuwasha usebenzisa iplamu eqhakaza ukwakheka kwezimbobo eziningi ukuze uhlanze phansi ibhodlela, ukusebenza kahle kokuwasha kuphezulu.

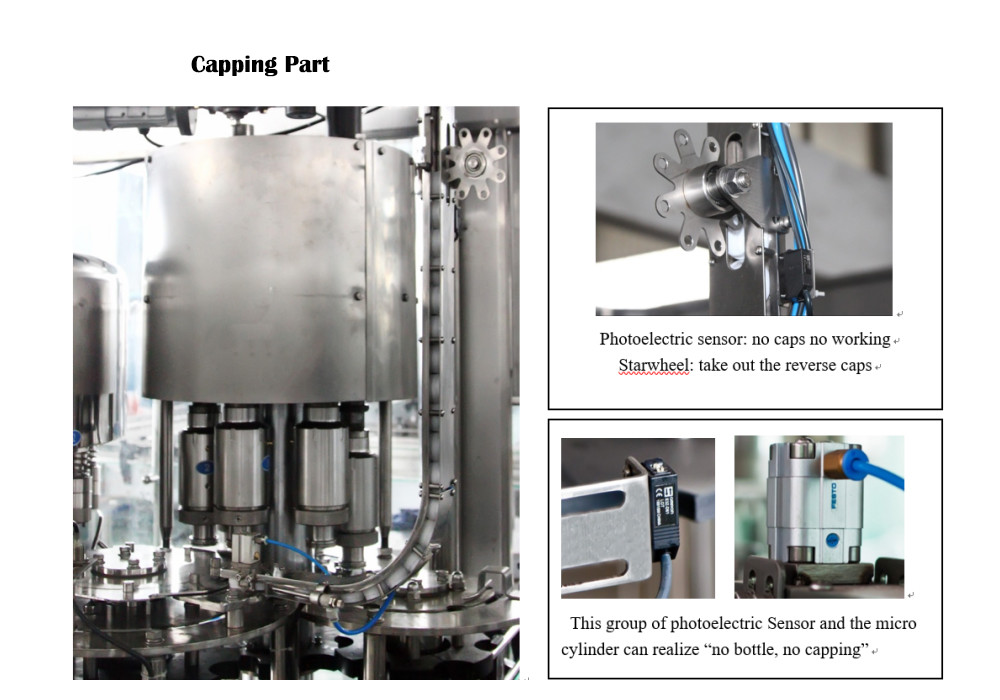

● Umshini we-capping usebenzisa ubuchwepheshe baseFrance, lokhu kwenziwa nge-torque kazibuthe; i-cap catching isebenzisa kabili ukubamba ukuqinisekisa ubuqiniso. Amandla wokuqhafaza ayahleleka, ukushaya i-torque njalo ngeke kulimaze amakepisi futhi ikepisi livalekile futhi lithembekile.

● Umshini wonke usebenza ngesikrini sokuthinta, esilawulwa yi-PLC kanye nesiguquli semvamisa njll, ngemisebenzi yokungabikho kokudla kwebhodlela, ukulinda lapho kushoda amabhodlela, ukuma uma ibhodlela livinjiwe noma kungekho cap ku-cap guiding pipe.

3.Cap Loader

I-cap loader idlulisa amakepisi emshinini we-cap unscrambling. Inomsebenzi wokungabikho kokulayishwa kwebhodlela, ukulawula okuzenzakalelayo.

Umthumeli webhodlela le-4